Design Criteria

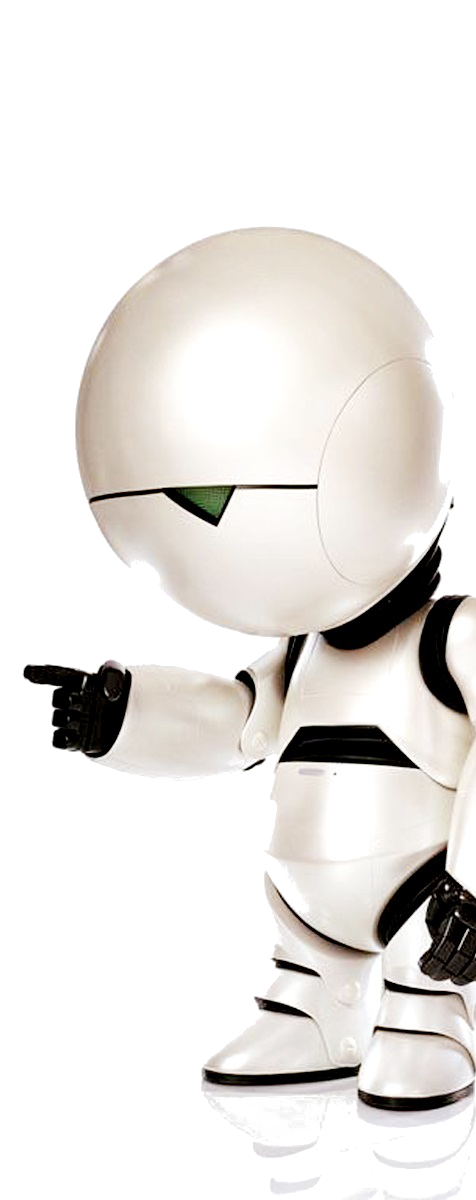

One of the technical goals of the Beer Robot project is to design and build every mechanical parts. We first have to select what will influence the design.

Since what we are making is a prototype ideas that must be followed to design it are:

- Thinking about large batchs for the production model

- Material choice according to the expected final product

- Reducing the number of parts to reduce labour cost

- Ease of assembly

- Reliable design for each parts and the entire assembly

- Ease of access to each parts for repair and debugging

- Taking in account the prototype manufacturing process

First we had a meeting to show each others our different ideas on the mechanical design of the robot.

Design Methodology

The chosen material was plastic because it's cheap, injection molding is efficient, it has good mechanical and chemical properties and ABS/PLA is available in the 3D printers. From this fact we can carry on the design.

The design process was devided in numerous steps:

- General design of each parts and the assembly.

- Concept faisability verification

- Adding necessary parts to improve the mechanical design of the assembly

- Taking in account the necessary tolerances due to the manufacturing process (3D printers mostly)

- Blending the parts together is possible to reduces their number ⇒ cost reduction for production

- Modifying the design lightly to improve the printing time or increase the stiffness of large parts (dependent of the manufacturing process)

Few different stages are shown in the following pictures.

CAD Files are available to download here

Parts Manufacturing Results

Therefore what is left to is to compute few ray traced pictures and manufacturing the parts.

As expected there was some modification to do afterward on most of the plastic parts. It was due to the fact that the Makerbot reliability and accuracy was lower than our expectations. Anyway we were able to print what we wanted to. Some parts are glued together with cyanoacrylate or epoxy resin and 2mm brass beams were used instead of the anticipated screws.