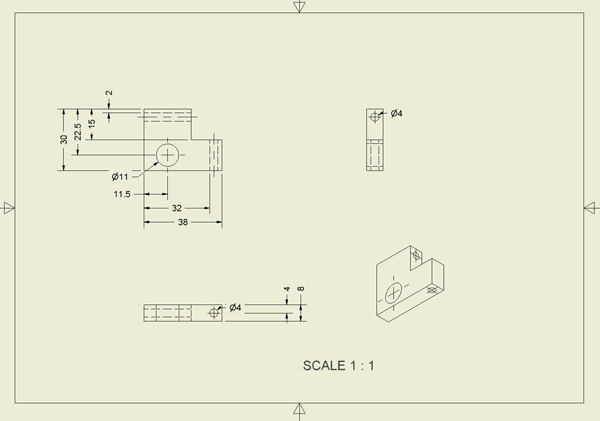

To attach the bearings to the base plate we need bearing holders. The holders were manufactured out of aluminium. The design is very simple. The aluminum holders have a very precise bore, precise enough to clamp the bearings in there. Since there is little to no axial force, the bearings are kept in place very easily. Furthermore, the holders contain more bores to allow us to screw them to the base plate.

The first drawing is that of the drive shaft bearing holders. These bearing are bigger, stronger and of a better quality than the other bearings. This means you will need different holders. You need four of these holders.

The second drawing is the design of the bearing holders for the ax on the 90 degree corner. The measurements of these holders are critical, since they need to make sure that all the axes are on one line, the vertical ones as well as the horizontal ones. You'll also need four of these.

The final drawing shows the design of the other eight bearing holders. The bearings are readily easy to find in a model building store. You'll need 16 of them, of which four that are of a high quality.

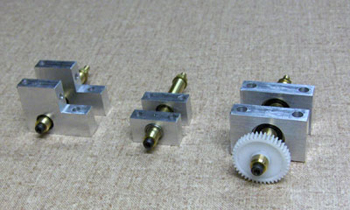

The several bearing holders.